People don´t often think about it, but virtually every human activity depend on gas. Industrial gases are used worldwide in virtually every branch of industry, commerce, science and research. Pharmaceutical and medical gas products and services enable healthcare professionals to provide optimal therapy to patients having difficulty breathing. It´s an essential part of our daily lifes.

Gas production and operation is a extremely complex matter. There are actually very few players in the world: LINDE, MESSER, AIR LIQUIDE, AIR PRODUCTS and small companies such as IBG.

It´s safe to say that gases, if applied correctly, provide increased profitability to any market!

Sometimes they can be a game changer.

Just a few examples of what gases can do. Pick your industry and check it out:

- Aquaculture

- Chemicals

- Contruction and Infrastructure

- Electronics

- Food and Beverages

- Healthcare

- Glass

- Laboratories

- Metal fabrication

- Oil and Gas

- Pharma and Biotech

- Plastics

- Power and Energy

- Pulp and Paper

- Refining

- Steel

- Transport

- Waste Incineration

- Water Treatment

Details about each gas properties and common applications.

There are countless types of gases, as you can find applications for mixtures as well, not just pure substances.

Depending on the industry and segment, you can call them commodities or high added value products. For example, food industries require specific gas blends to efficiently preserve flavor and taste before reaching final consumers. Therefore, they rely on advanced chemical labs to produce exactly what they need.

Since 2018, our CTO Juliana Merege has worked for White Martins, the Brazilian subsidiary of Linde, and Messer, both companies of 100+ years of background throught the world. In present day, those are the top 2 leading players in Latin America. During the time at White Martins, Juliana led the Production Unit “Uberlândia”, a logistic hub in a countryside region known as “Triângulo Mineiro”, supplying a challenging geografical area as large as Portugal.

Air separation

Unlike oil, that is deeply buried in soil or ocean bottom, gases are available in atmosferic air. So, you just need to know how to separate air components to isolate the gas you want, meaning that Air Separation Plants (aka Airs Separation Units – ASU) basically need 2 utilities to work: Electric Power and Water. Other ingredients are available for free in nature.

That is a huge advantage for the segment, as plants can be built anywhere around the globe. 95 countries have at least one of those facilites.

This is already old technology, as it started in 1895 by Carl Von Linde, a german scientist and entrepreneur. Little has changed over the years, since the process is absolutelly ingenious and efficient.

Air Separation Plants are continuously operated (24/7) and, although the concept is fairly simple, they encompass hundreds of equipments, so much that sometimes the facility may resemble a refinery.

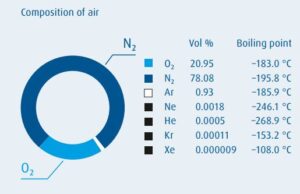

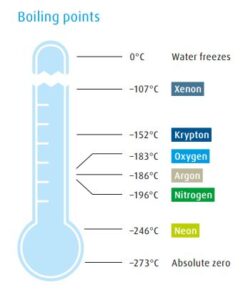

To enable air to be separated into its constituents by means of rectification – the actual separation process – a large part of the air volume used must be liquefied.

A gas can only be transformed into a liquid state at temperature and pressure conditions below those of its critical point. The critical point of air is Tcrit = –140.7ºC

(132.5 K) and Pcrit = 37.7 bar. In other words, air can be liquefied only at temperatures below –140.7ºC (132.5 K).

If you wish to separate Xenon, for example, you just have to freeze air at any temperature between -107C and – 151.99C.

A more appropriate term for the process is Cryogenic Air Separation or Retification.

Rectification is synonymous with countercurrent distillation. This special distillation process enables the individual components of a mixture to be separated with a high purity combined with a good yield, even when their boiling points are relatively close to each other. Most industries are interested in Oxygen, Nitrogen, Argon and CO2, so it´s not worth it to try to isolate Neon.

The Retification is the core of Air Separation Units (ASU) and it happens typically inside 2 columns of around 15 meters each.

Largest ASU in the world is in Jamnagar, India. It has started up in 2017 and it´s owned by Linde. Production average of pure oxygen is around 5200 tonnes per day.

Gas Production Units

After you isolated the gas you want – say, oxygen – you now need to safely transport it to logistics hubs and continue the way to final costumers. However, in order to make it feasible financially and operationally, your production must be liquified. Reason is simple. Liquids are more dense than gas, meaning there is much more product mass in the same volume, so it saves costs in logistics, plus it prevents incidents during transportation.

The liquidified pure gas is then transported in adapted vehicules that keep them at extremely low temperatures along the way.

In national emergencies, such the COVID pandemic, market players have partnered with government to bring oxygen to remote locations in Latin America in record time.

Brazillian Navy (MB) and Air Force (FAB) have a enourms role in this segment logistics, which is essential to National Security.

While working for White Martins in 2019 and 2020, Juliana Merege managed the installation, startup and daily operation of a new cryogenic tank, of 47.000 m3 of capacity, the largest volume available for this industry. This allowed an increase in production by a factor of 2.2 and, when the COVID pandemic struck in March 2020, the facility was prepared to supply hospital demands in the very vast geografic region and it even contributed to humanitarian efforts for the city of Manaus in the darkest days of the crisis in 2021.

Packaged Gases

The logistics hub is also the unit that receives the liquidified product, brings it back to gas and storages it in cylinders.

High-pressure cylinders are ideal to safely transport, use and store most compressed gases. It is typically around 200kPa, which involves great operational risk and exposes this industry to many international regulations and requires a great deal of HSE (Health, Safety and Environment) knowledge.

Some gases, mainly Oxygen and Nitrous Oxide, can also be applied in Healthcare and therefore are called Medicinal Gases. Production is the same as Industrial Gases in general, but requires aditional purification and laboratory validation, as well as a regular report to government Health Authorities, which can be rather strict. In Brazil, there is ANVISA.

However, acetylene is supplied in specific cylinders to ensure safety, in a much lower pressure and low concentration. Acetylene is an exception from other gases, mainly because it does not exist in air. It is fully sintetized by a chemical reaction between Calcium Carbide (an ore) and water, a very controlled chemical plant, completely different from the retification process previously explained. This also takes place in the logistic hub, so it´s fair to say this a Gas Production Facility.

After compressing gases and filling the cylinders, those are carried in trucks to final destinations, such as hospitals, residential areas and virtually every industry that may require them (see the examples in the begging of this Business Case).

If demand is strong enough, the organization may even install a dedicated plant right next to the costumer and create pipelines that supply the gases right into clients equipments, without needing any vehicule and maybe not even cylinders.

Bulk and Microbulk Delivery

Bulk gases can be supplies by several methods: stationary cylinders, horizontally-mounted tube trailers, or pipelines. The stationary cylinder must be refilled periodically from a gas line or cryogenic tank trailer. Cryogenic tank trailers can deliver liquid gas in bulk form. Pipeline delivery is only available in areas near a gas production plant.

Business Opportunities in Latin America

In the last few years, the segment of Industrial & Medicinal Gases made new interesting movements and increased interface with other markets.

- Supply for aerospace industry – Linde

- Green hydrogen – Linde (White Martins) plant in Pecem, Brazil.

- Innovative solutions for Beverage industry – Messer

- New applications for High Purity Oxygen Market Size

- Post-COVID new regulations for cylinders transportation

- New aircraft for better cylinder transportation and humanitarian support

Please, check out other KEY ON-GOING BUSINESS CASES at Brazilian Air Force (FAB), Brazilian Navy and other opportunities for Latin America:

- BUSINESS CASE FAB / AEB “ALCANTARA launching base”

- BUSINESS CASE FAB – CARPONIS-1 / HR Remote Sensing

- BUSINESS CASE SMART AGRICULTURE – NB-IoT

- BUSINESS CASE INPE REMOTE SENSING SATELLITE “AMAZONIA-1”

- BUSINESS CASE INPE REMOTE SENSE SATELLITE “CBERS”

- BUSINESS CASE ELETROBRAS – HYDROELETRIC POWER

- BUSINESS CASE VALE – ENERGY STORAGE

- BUSINESS CASE MB “UNMANNED AIRCRAFT”

- BUSINESS CASE SISFRON – BRAZILIAN TERRESTRIAL BORDER

- BUSINESS CASE “AMAZÔNIA AZUL”

- BUSINESS CASE BRAZILIAN NAVY NUCLEAR PROGRAM

- BUSINESS CASE AIRCRAFTS SAAB F-39E GRIPEN

- BUSINESS CASE MB “ANTI-SHIP MISSILE”

- BUSINESS CASE MB “TAMANDARÉ FRIGATES”

If your company is interested in opportunities such as those above, please let us know. MEREGE would be more than glad to act as your bridge into Brazil.

Unfolding relationships previously developed, MEREGE partners are able to quickly build a specific network that reaches the market the costumer needs.

MEREGE Legal & Regulatory team has a long and vast knowledge and experience, hence able to help your company to set the safest and the strongest path.

Always count on the widely respected experience and networking of MEREGE Consulting Partners to reach out to the right people at the right time.