The main reasons for miniaturizing satellites is to reduce the cost of its production, launch and deployment, as they would often be suitable for launching in multiples.

Nanosatelites , even using the excess capacity of larger existing launch vehicles.

We categorize miniature satellites using a criteria based on mass:

- Minisatellite or smallsatellite (100–500 kg (220–1,100 lb))

- Microsatellite (10–100 kg (22–220 lb))

- Nanosatellite (1–10 kg (2.2–22.0 lb)) – include 1U CUBE SATs

- Picosatellite (0.1–1 kg (0.22–2.20 lb))

- Femtosatellite (0.01–0.1 kg (0.022–0.220 lb))

A 1U CubeSat size is at the edge between 2 genres – the nanosatellites and the picosatellites – but often referred to as nanosatellites.

Nanosatellites / CubeSat design

Designs and proposed designs of these types may be launched individually, but ideally or they should be launched im multiples, as nanosatellites useally work together or in formation, reason why sometimes the term “satellite swarm” or “fractionated spacecraft” may be applied. Some designs require a larger “mother” satellite for communication with ground controllers or for launching and docking with nanosatellites.

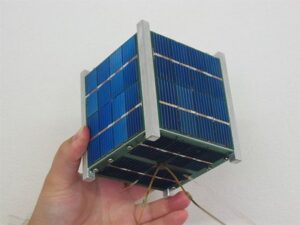

The CubeSat concept was first developed in 1999 by a collaborative team of California Polytechnic State University and Stanford University. The specifications, to be used by anyone planning to launch a CubeSat-style nanosatellite, are maintained by this group. Over 1600 nanosatellites have been launched as of August 2021.

The nanosat option would allow more nations to own their own satellite for off-peak (non-disaster) imaging data collection. As costs lower and production times shorten, nanosatellites are becoming increasingly feasible ventures for a variety of companies.

Nanosat market

In the ten years of nanosat launches prior to 2014, only 75 nanosats were launched. Launch rates picked up substantially when in the three-month period from November 2013–January 2014 when 94 nanosats were launched.

One challenge of using nanosats has been the economic delivery of such small satellites to anywhere beyond low Earth orbit. By late 2014, proposals were being developed for larger spacecraft specifically designed to deliver swarms of nanosats to trajectories that are beyond Earth orbit for applications such as exploring distant asteroids.

The CubeSat design minimizes risk to the launch vehicle and to the rest of the payload. Encapsulation of the launcher–payload interface takes away the amount of work that would previously be required for mating a piggyback satellite with its launcher. Unification among payloads and launchers enables quick exchanges of payloads and utilization of launch opportunities on short notice.

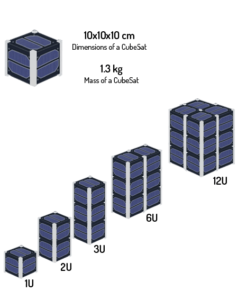

Standard CubeSats are made up of 10 cm × 10 cm × 11.35 cm (3.94 in × 3.94 in × 4.47 in) units, designed to provide 10 cm × 10 cm × 10 cm (3.9 in × 3.9 in × 3.9 in) or 1 l (0.22 imp gal; 0.26 US gal) of useful volume while weighing no more than 1.33 kg (2.9 lb) per unit.

The smallest standard size is 1U, while 3U+ is composed of three units stacked lengthwise with an additional 6.4 cm (2.5 in) diameter cylinder centered on the long axis and extending 3.6 cm (1.4 in) beyond one face.

Since nearly all CubeSats are 10 cm × 10 cm (3.9 in × 3.9 in) (regardless of length) they can all be launched and deployed using a common deployment system called a Poly-PicoSatellite Orbital Deployer (P-POD), developed and built by Cal Poly.

In recent years, larger CubeSat platforms have been developed, most commonly 6U (10 cm × 20 cm × 30 cm (3.9 in × 7.9 in × 11.8 in) or 12 cm × 24 cm × 36 cm (4.7 in × 9.4 in × 14.2 in) and 12U (20 cm × 20 cm × 30 cm (7.9 in × 7.9 in × 11.8 in)) or 24 cm × 24 cm × 36 cm (9.4 in × 9.4 in × 14.2 in), to extend the capabilities of CubeSats beyond academic and technology validation applications and into more complex science and national defense goals.

With continued advances in the miniaturization and capability increase of electronic technology and the use of satellite constellations, nanosatellites are increasingly capable of performing commercial missions that previously required microsatellites or higher. For example, a 6U CubeSat standard has been proposed to enable a satellite constellation of 35 8 kg (18 lb) Earth-imaging satellites to replace a constellation of five 156 kg (344 lb) RapidEye Earth-imaging satellites, at the same mission cost, with significantly increased revisit times: every area of the globe would be imaged every 3.5 hours rather than the once per 24 hours with the RapidEye constellation. More rapid revisit times are a significant improvement for nations performing, for instance, disaster response, which was the purpose of the RapidEye constellation.

Care must be taken in electronics selection to ensure the devices can tolerate the radiation present. For very low Earth orbits (LEO) in which atmospheric reentry would occur in just days or weeks, radiation can largely be ignored and standard consumer grade electronics may be used. Consumer electronic devices can survive LEO radiation for that time as the chance of a single event upset (SEU) is very low.

Spacecraft in a sustained low Earth orbit lasting months or years are at risk and only fly hardware designed for and tested in irradiated environments. Missions beyond low Earth orbit or which would remain in low Earth orbit for many years must use radiation-hardened devices. Further considerations are made for operation in high vacuum due to the effects of sublimation, outgassing, and metal whiskers, which may result in mission failure.

Attitude control

Attitude control (orientation) for CubeSats relies on miniaturizing technology without significant performance degradation. Tumbling typically occurs as soon as a CubeSat is deployed, due to asymmetric deployment forces and bumping with other CubeSats. Some CubeSats operate normally while tumbling, but those that require pointing in a certain direction or cannot operate safely while spinning, must be detumbled.

Systems that perform attitude determination and control include reaction wheels, magnetorquers, thrusters, star trackers, Sun sensors, Earth sensors, angular rate sensors, GPS receivers and antennas. Combinations of these systems are typically seen in order to take each method’s advantages and mitigate their shortcomings. Reaction wheels are commonly utilized for their ability to impart relatively large moments for any given energy input, but reaction wheel’s utility is limited due to saturation, the point at which a wheel cannot spin faster.

Reaction wheels can be desaturated with the use of thrusters or magnetorquers. Thrusters can provide large moments by imparting a couple on the spacecraft but inefficiencies in small propulsion systems cause thrusters to run out of fuel rapidly. Commonly found on nearly all CubeSats are magnetorquers which run electricity through a solenoid to take advantage of Earth’s magnetic field to produce a turning moment. Attitude-control modules and solar panels typically feature built-in magnetorquers. For CubeSats that only need to detumble, no attitude determination method beyond an angular rate sensor or electronic gyroscope is necessary.

Pointing in a specific direction is necessary for Earth observation, orbital maneuvers, maximizing solar power, and some scientific instruments. Directional pointing accuracy can be achieved by sensing Earth and its horizon, the Sun, or specific stars. Sinclair Inter planetary’s SS-411 sun sensor and ST-16 star tracker both have applications for CubeSats and have flight heritage. Pumpkin’s Colony I Bus uses an aerodynamic wing for passive attitude stabilization. Determination of a CubeSat’s location can be done through the use of on-board GPS, which is relatively expensive for a CubeSat, or by relaying radar tracking data to the craft from Earth-based tracking systems.

Propulsion

CubeSat propulsion has made rapid advancements in the following technologies: cold gas, chemical propulsion, electric propulsion, and solar sails.

The biggest challenge with CubeSat propulsion is preventing risk to the launch vehicle and its primary payload while still providing significant capability. Components and methods that are commonly used in larger satellites are disallowed or limited, and the CubeSat Design Specification (CDS) requires a waiver for pressurization above 1.2 atm (120 kPa), over 100 Wh of stored chemical energy, and hazardous materials.

Those restrictions pose great challenges for CubeSat propulsion systems, as typical space propulsion systems utilize combinations of high pressures, high energy densities, and hazardous materials. Beyond the restrictions set forth by launch service providers, various technical challenges further reduce the usefulness of CubeSat propulsion. Gimbaled thrust cannot be used in small engines due to the complexity of gimbaling mechanisms, thrust vectoring must instead be achieved by thrusting asymmetrically in multiple-nozzle propulsion systems or by changing the center of mass relative to the CubeSat’s geometry with actuated components.

Small motors may also not have room for throttling methods that allow smaller than fully on thrust, which is important for precision maneuvers such as rendezvous. CubeSats which require longer life also benefit from propulsion systems. When used for orbit keeping, a propulsion system can slow orbital decay.

- Cold gas thrusters:

A cold gas thruster typically stores inert gas, such as nitrogen, in a pressurized tank and releases the gas through a nozzle to produce thrust. Operation is handled by just a single valve in most systems, which makes cold gas the simplest useful propulsion technology. Cold gas propulsion systems can be very safe since the gases used do not have to be volatile or corrosive, though some systems opt to feature dangerous gases such as sulfur dioxide. This ability to use inert gases is highly advantageous to CubeSats as they are usually restricted from hazardous materials. Unfortunately, only low performance can be achieved with them, preventing high impulse maneuvers even in low mass CubeSats. Due to this low performance, their use in CubeSats for main propulsion is limited and designers choose higher efficiency systems with only minor increases in complexity. Cold gas systems more often see use in CubeSat attitude control.

- Chemical propulsion:

Chemical propulsion systems use a chemical reaction to produce a high-pressure, high-temperature gas that accelerates out of a nozzle. Chemical propellant can be liquid, solid or a hybrid of both. Liquid propellants can be a monopropellant passed through a catalyst, or bipropellant which combusts an oxidizer and a fuel. The benefits of monopropellants are relatively low-complexity/high-thrust output, low power requirements, and high reliability. Monopropellant motors tend to have high thrust while remaining comparatively simple, which also provides high reliability. These motors are practical for CubeSats due to their low power requirements and because their simplicity allows them to be very small. Small hydrazine fueled motors have been developed, but may require a waiver to fly due to restrictions on hazardous chemicals set forth in the CubeSat Design Specification. Safer chemical propellants which would not require hazardous chemical waivers are being developed, such as AF-M315 (hydroxylammonium nitrate) for which motors are being or have been designed. A “Water Electrolysis Thruster” is technically a chemical propulsion system, as it burns hydrogen and oxygen which it generates by on-orbit electrolysis of water.

- Electric propulsion:

CubeSat electric propulsion typically uses electric energy to accelerate propellant to high speed, which results in high specific impulse. Many of these technologies can be made small enough for use in nanosatellites, and several methods are in development. Types of electric propulsion currently being designed for use in CubeSats include Hall-effect thrusters, ion thrusters, pulsed plasma thrusters, electrospray thrusters, and resistojets. Several notable CubeSat missions plan to use electric propulsion, such as NASA’s Lunar IceCube. The high efficiency associated with electric propulsion could allow CubeSats to propel themselves to Mars. Electric propulsion systems are disadvantaged in their use of power, which requires the CubeSat to have larger solar cells, more complicated power distribution, and often larger batteries. Furthermore, many electric propulsion methods may still require pressurized tanks to store propellant, which is restricted by the CubeSat Design Specification. The ESTCube-1 used an electric solar-wind sail, which relies on an electromagnetic field to act as a sail instead of a solid material. This technology used an electric field to deflect protons from solar wind to produce thrust. It is similar to an electrodynamic tether in that the craft only needs to supply electricity to operate.

- Solar sail:

Solar sails (also called light sails or photon sails) are a form of spacecraft propulsion using the radiation pressure (also called solar pressure) from stars to push large ultra-thin mirrors to high speeds, requiring no propellant. The force from a solar sail scales with the sail’s area, this makes sails well suited for use in CubeSats as their small mass results in the greater acceleration for a given solar sail’s area. However, solar sails still need to be quite large compared to the satellite, which means useful solar sails must be deployed, adding mechanical complexity and a potential source of failure. This propulsion method is the only one not plagued with restrictions set by the CubeSat Design Specification, as it does not require high pressures, hazardous materials, nor significant chemical energy. Few CubeSats have employed a solar sail as its main propulsion and stability in deep space, including the 3U NanoSail-D2 launched in 2010, and the LightSail-1 in May 2015. CubeSail is currently testing in orbit a 260-metre (850 ft)-long, 20 m2 (220 sq ft) solar sail ribbon extended between two CubeSats, that will inform the design for a much larger concept called UltraSail heliogyro. LightSail-2 successfully deployed on a Falcon Heavy rocket in 2019, while at least one CubeSat that was planned to launch on the Space Launch System’s first flight (Artemis 1) in 2021 is set to use a solar sail: the Near-Earth Asteroid Scout (NEA Scout).

Winglet solar panels increase surface area for power generation.

CubeSats use solar cells to convert solar light to electricity that is then stored in rechargeable lithium-ion batteries that provide power during eclipse as well as during peak load times. These satellites have a limited surface area on their external walls for solar cells assembly, and has to be effectively shared with other parts, such as antennas, optical sensors, camera lens, propulsion systems, and access ports. Lithium-ion batteries feature high energy-to-mass ratios, making them well suited to use on mass-restricted spacecraft. Battery charging and discharging is typically handled by a dedicated electrical power system (EPS). Batteries sometimes feature heaters to prevent the battery from reaching dangerously low temperatures which might cause battery and mission failure.

The rate at which the batteries decay depends on the number of cycles for which they are charged and discharged, as well as the depth of each discharge: the greater the average depth of discharge, the faster a battery degrades. For LEO missions, the number of cycles of discharge can be expected to be on the order of several hundred.

If it happens that the spacecraft is launched into a sun-synchronous orbit, the amount of eclipse time will dwindle, allowing fewer interruptions of continuous solar irradiation for the PV cells and thus reducing the battery capacity requirements. In LEO sun-synchronous orbits, however, the spacecraft will not always experience sunlight, and so depending on the time of year, the spacecraft may need to gain altitude to again be in the line of sight to the sun. Due to size and weight constraints, common CubeSats flying in LEO with body-mounted solar panels have generated less than 10 W. Missions with higher power requirements can make use of attitude control to ensure the solar panels remain in their most effective orientation toward the Sun, and further power needs can be met through the addition and orientation of deployed solar arrays. Recent innovations include additional spring-loaded solar arrays that deploy as soon as the satellite is released, as well as arrays that feature thermal knife mechanisms that would deploy the panels when commanded. CubeSats may not be powered between launch and deployment, and must feature a remove-before-flight pin which cuts all power to prevent operation during loading into the P-POD. Additionally, a deployment switch is actuated while the craft is loaded into a P-POD, cutting power to the spacecraft and is deactivated after exiting the P-POD.

Telecommunications

The low cost of CubeSats has enabled unprecedented access to space for smaller institutions and organizations but, for most CubeSat forms, the range and available power is limited to about 2W for its communications antenna.

Because of tumbling and low power range, radio-communications are a challenge.

Many CubeSats use an omnidirectional monopole or dipole antenna built with commercial measuring tape. For more demanding needs, some companies offer high-gain antennae for CubeSats, but their deployment and pointing systems are significantly more complex. For example, MIT and JPL are developing an inflatable dish antenna with a useful range to the Moon but appears to be poorly efficient. JPL has successfully developed X-band and Ka-band high-gain antennas for MarCO and Radar in a CubeSat (RaInCube) missions.

Antennas

Traditionally, Low Earth Orbit Cubesats use antennas for communication purpose at UHF and S-band. To venture further in the solar system, larger antennas compatible with the Deep Space Network (X-band and Ka-band) are required. JPL‘s engineers developed several deployable high-gain antennas compatible with 6U-class CubeSats for MarCO and Near-Earth Asteroid Scout. JPL‘s engineers have also developed a 0.5 m (1 ft 8 in) mesh reflector antenna operating at Ka-band and compatible with the DSN that folds in a 1.5U stowage volume. For MarCO, JPL‘s antenna engineers designed a Folded Panel Reflectarray (FPR) to fit on a 6U Cubesat bus and supports X-band Mars-to-Earth telecommunications at 8kbit/s at 1AU.

Thermal management

Different CubeSat components possess different acceptable temperature ranges, beyond which they may become temporarily or permanently inoperable. Satellites in orbit are heated by radiative heat emitted from the Sun directly and reflected off Earth, as well as heat generated by the craft’s components. CubeSats must also cool by radiating heat either into space or into the cooler Earth’s surface, if it is cooler than the spacecraft. All of these radiative heat sources and sinks are rather constant and very predictable, so long as the CubeSat’s orbit and eclipse time are known.

Components used to ensure the temperature requirements are met in CubeSats include multi-layer insulation and heaters for the battery. Other spacecraft thermal control techniques in small satellites include specific component placement based on expected thermal output of those components and, rarely, deployed thermal devices such as louvers. Analysis and simulation of the spacecraft’s thermal model is an important determining factor in applying thermal management components and techniques. CubeSats with special thermal concerns, often associated with certain deployment mechanisms and payloads, may be tested in a thermal vacuum chamber before launch. Such testing provides a larger degree of assurance than full-sized satellites can receive, since CubeSats are small enough to fit inside of a thermal vacuum chamber in their entirety. Temperature sensors are typically placed on different CubeSat components so that action may be taken to avoid dangerous temperature ranges, such as reorienting the craft in order to avoid or introduce direct thermal radiation to a specific part, thereby allowing it to cool or heat.

Costs

CubeSat launch prices have been about $100,000 per unit, but newer operators are offering lower pricing. A typical price to launch a 1U cubesat with a full service contract (including end-to-end integration, licensing, transportation etc.) was about $60,000 in 2021. A basic 1U CubeSat can cost about $50,000 just to construct.

Some CubeSats have complicated components or instruments, such as LightSail-1, that pushes their construction cost into the millions of dollars, but a basic 1U CubeSat can cost about $50,000 to construct. So, CubeSats are a viable option for some schools and universities; as well as small businesses to develop CubeSats for commercial purposes.

Launch vehicle

Since nearly all CubeSats are 10 cm × 10 cm (3.9 in × 3.9 in) (regardless of length) they can all be launched and deployed using a common deployment system called a Poly-PicoSatellite Orbital Deployer (P-POD), developed and built by Cal Poly.

A number of commercial and military-contractor companies have been developing microsatellite launch vehicles to perform the increasingly targeted launch requirements of microsatellites & picosatellites. While microsatellites have been carried to space for many years as secondary payloads aboard larger launchers, the secondary payload paradigm does not provide the specificity required for many increasingly sophisticated small satellites that have unique orbital and launch-timing requirements.

In April 2013, Garvey Spacecraft was awarded a US$200,000 contract to evolve their Prospector 18 suborbital launch vehicle technology into an orbital nanosat launch vehicle capable of delivering a 10 kg (22 lb) payload into a 250 km (160 mi) orbit to an even-more-capable clustered “20/450 Nano/Micro Satellite Launch Vehicle” (NMSLV) capable of delivering 20 kg (44 lb) payloads into 450 km (280 mi) circular orbits.

The Boeing Small Launch Vehicle was an air-launched three-stage-to-orbit launch vehicle concept aimed to launch small payloads of 45 kg (100 lb) into low Earth orbit. The program is proposed to DARPA to drive down launch costs for U.S. military small satellites to as low as US$300,000 per launch ($7,000/kg). Unfortunately, Boeing dropped it down on early 2020.

The Swiss company Swiss Space Systems (S3) has announced plans in 2013 to develop a suborbital spaceplane named SOAR that would launch a microsat launch vehicle capable of putting a payload of up to 250 kg (550 lb) into low Earth orbit.

The Spanish company PLD Space born in 2011 with the objective of developing low cost launch vehicles called Miura 1 and Miura 5 with the capacity to place up to 150 kg (330 lb) into orbit.

On the heels of its first successful orbital launch in January 2022, Virgin Orbit geared up for its first operational mission on March 2022, with a flight of its air-launched rocket off the coast of California to deploy seven small satellites. Virgin Orbit’s two-stage rocket was mounted under the left wing of the company’s Boeing 747 carrier aircraft.

Nanosatellite launch vehicle

With the emergence of the technological advances of miniaturization and increased capital to support private spaceflight initiatives, several startups have been formed to pursue opportunities with developing a variety of small-payload Nanosatellite Launch Vehicle (NLV) technologies.

NLVs proposed or under development include:

Virgin Orbit LauncherOne upper stage, intended to be air-launched from WhiteKnightTwo similar to how the SpaceShipTwo spaceplane is launched.

Ventions’ Nanosat upper stage.

Nammo/Andøya North Star (polar orbit-capable launcher for a 10 kg payload)

Garvey Spacecraft (now Vector Launch) is evolving their Prospector 18 suborbital launch vehicle technology into an orbital nanosat launch vehicle capable of delivering a 10 kg (22 lb) payload into a 250 km (160 mi) orbit.

Generation Orbit is developing an air-launched rocket to deliver both nanosats and sub-50 kg microsats to low Earth orbit.

Actual NS launches:

NASA launched three satellites on 21 April 2013 based on smart phones. Two phones use the PhoneSat 1.0 specification and the third used a beta version of PhoneSat 2.0

ISRO launched 14 nanosatellites on 22 June 2016, 2 for Indian universities and 12 for the United States under the Flock-2P program. This launch was performed during the PSLV-C34 mission.

ISRO launched 103 nanosatellites on 15 February 2017. This launch was performed during the PSLV-C37 mission.

CubeSat Market / NB IoT in Brazil

Brazilian market for CUBESATs at Universities

In Brazil, among other Universities similar initiatives, we would highlight the Northeast Regional Center (CRN) of the National Institute of Space Research (INPE). They have developed, along with the Federal University of Rio Grande do Norte (UFRN), the so called CONASAT project, with the objective of developing a constellation of nanosatellites to the Brazilian Environmental Data Collection System (SBCDA).

Currently, it has been developed the CubeSat called CONASAT-0 (first of the constellation), which needs the implementation of an on-board control system capable of meeting requirements of the CONASAT project. In this context, this work presents the first version of the on-board control system for CONASAT-0. From the Narrow band applications, such as IoT.

A reliable TT&C plus PDT (Payload Data Transmission) systems combined in the ground station service is essential for optimizing the application performance

Picosatellites

An artificial satellites with a wet mass between 0.1 and 1 kg (0.22 and 2.2 lb.

Designs of these types usually have multiple picosatellites working together or in formation (sometimes the term “swarm” is applied). Some designs require a larger “mother” satellite for communication with ground controllers or for launching and docking with picosatellites.

Picosatellites are emerging as a new alternative for do-it-yourself kit builders. Picosatellites are currently commercially available across the full range of 0.1–1 kg (0.22–2.2 lb). Launch opportunities are now available for $12,000 to $18,000 for sub-1 kg picosat payloads that are approximately the size of a soda can.

Femtosatellites

An artificial satellites with a wet mass below 100 g (3.5 oz). Like picosatellites, some designs require a larger “mother” satellite for communication with ground controllers.

Three prototype “chip satellites” were launched to the ISS on Space Shuttle Endeavour on its final mission in May 2011. They were attached to the ISS external platform Materials International Space Station Experiment (MISSE-8) for testing.

In March 2019, the CubeSat KickSat-2 deployed 105 femtosats called “ChipSats” into Earth orbit. The satellites were tested for 3 days, and they then reentered the atmosphere and burned up.

For more information on related business opportunities, please check it out for the USE CASES below:

USE CASE “NB-IoT”

USE CASE “ORBIT TYPES”

USE CASE “OFFSHORE & MINING TELEMEDICINE”

USE CASE “REMOTE MINING”

Please, also check it out for the other KEY ON-GOING BUSINESS CASES at Brazilian Air Force (FAB):

BUSINESS CASE FAB / TELEBRAS “SGDC-1 / SGDC-2 plus TT&C COPE”

BUSINESS CASE FAB / AEB “ALCANTARA launching base”

BUSINESS CASE INPE REMOTE SENSE SATELLITE “CBERS”

BUSINESS CASE INPE REMOTE SENSING SATELLITE “AMAZONIA-1”

Please, also check it out for the KEY ON-GOING BUSINESS CASES at Brazilian Navy:

BUSINESS CASE MB “UNMANNED AIRCRAFT”

BUSINESS CASE MB “ANTI-SHIP MISSILES”

BUSINESS CASE MB “TAMANDARÉ FRIGATES”

If your company is interest on opportunities such as those above, please let us know. MEREGE would be more than glad to act as your bridge into Brazil.

Unfolding relationships previously developed, MEREGE partners were able to quickly build a specific network that would permeates the capillarity of aerospace sector.

MEREGE Legal & Regulatory team (LEGAL SERVICES PAGE), has a long and vast knowledge and experience, hence able to help your company to set the safest and the strongest path to this promising market.

Always count on the widely respected experience and networking of MEREGE Consulting Partners to reach out to the right people at the right time.